Cellular Lightweight Concrete Ppt

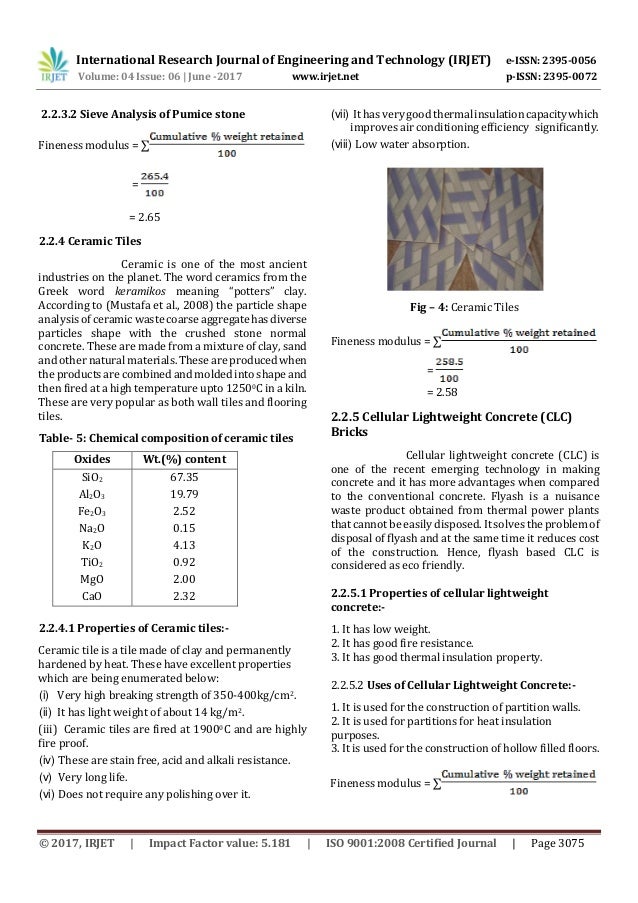

Light weight cellular concrete blocks are casted with 65 of fly ash and 35 of cement with foam content 1 5 of total weight and to increase its strength sand and quarry dust is added in its composition which replace fly ash upto 30 at an interval of 5.

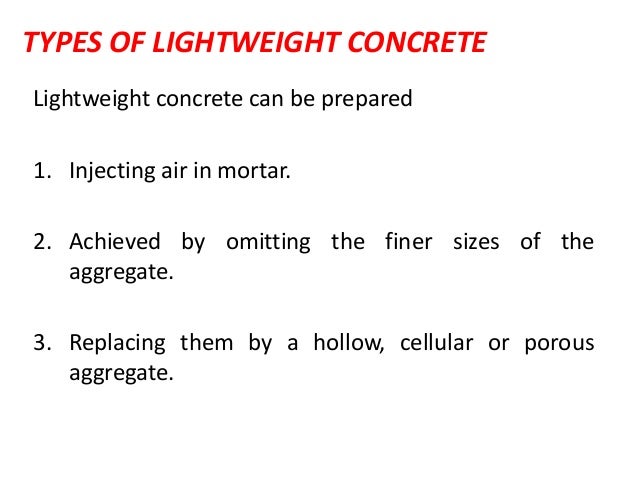

Cellular lightweight concrete ppt. Cellular concrete is a mixture of cement water and preformed foam. When cellular concrete hardens it has an oven dry density of 50 lb ft3 8 t m3 or less. To achieve the above principle practically there are 3 different ways. The mixed slurry is then poured into moulds of pre cast blocks structural components assembled form work of building elements or over flat roofs for thermal.

Cellular light weight concrete doc light wight concrete seminar reports docx lightweight concrete report ppt. By replacing the conventional aggregates by cellular porous aggregates light weight agg. Foam concrete is a type of aerated lightweight concrete. Although there are a number of lightweight cementitious materials the key differentiating factor between cellular concrete and other lightweight cementitious materials is the use of externally generated foam to reduce the density.

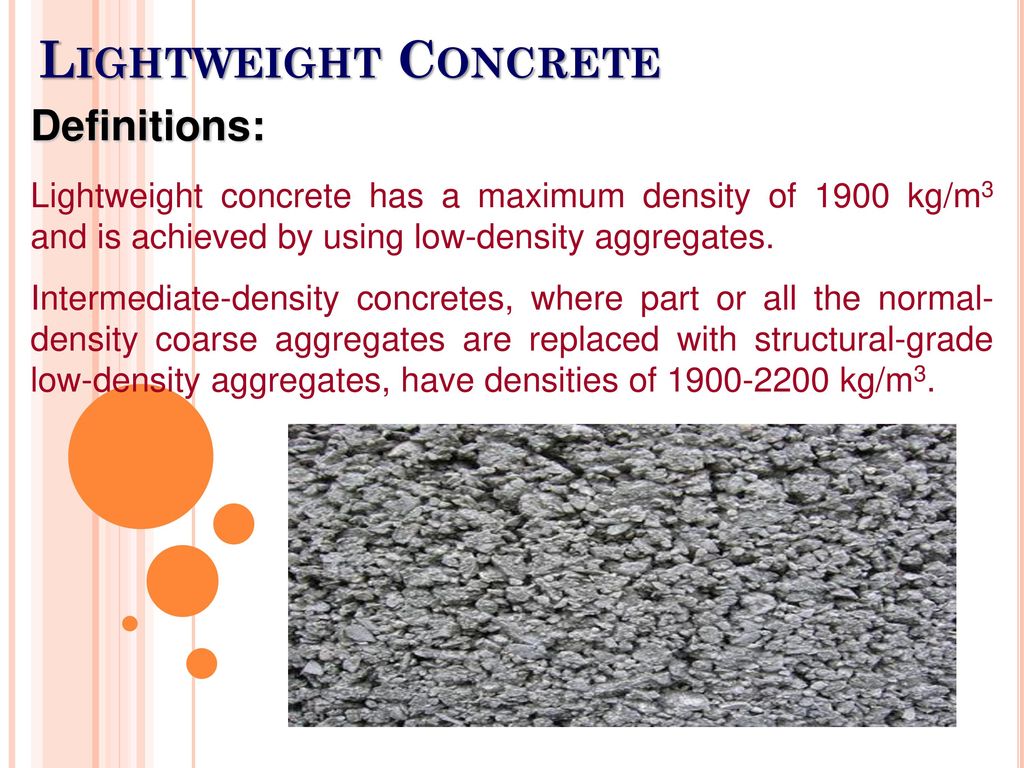

Foam concrete does not contain coarse aggregate and can be regarded as an aerated mortar. Cellular concrete may go by other names including foam cement foamed concrete or lightweight flowable fill. Lightweight concrete is a special concrete which weighs lighter than conventional concrete. Download lightweight concrete seminar reports ppt pdf lightweight concrete seminar topics abstracts full documentation source code.

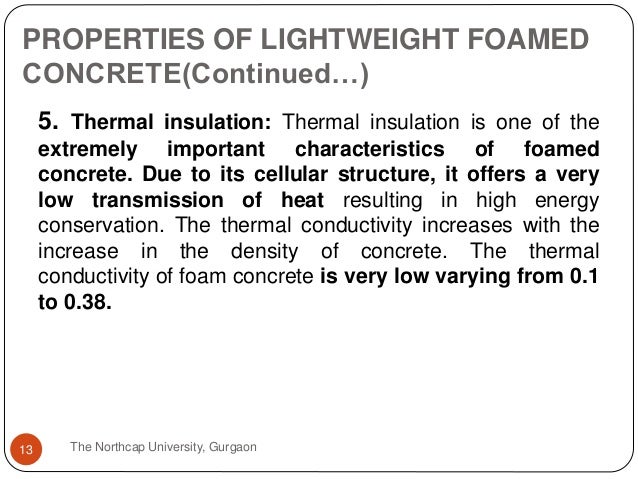

Density of this concrete is considerably low 300kg m3 to 1850kg m3 when compared to normal concrete. The use of fly ash lightweight concrete gives a planned answer for building development. It may also be defined as. By omitting the sand from the concrete no fines concrete.

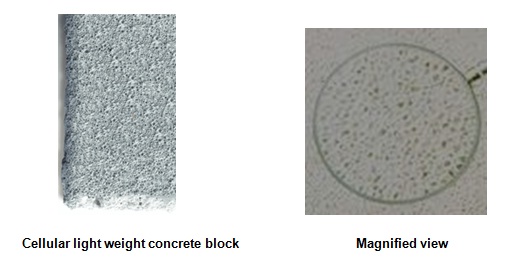

Foam concrete is produced when pre formed foam is added to slurry the function of foam is to create an air voids in cement based slurry. Properties of cellular lightweight concrete blocks. By incorporating the air or gas bubbles in concrete aerated concrete. Also explore the seminar topics paper on cellular lightweight concrete with abstract or synopsis documentation on advantages and disadvantages base paper presentation slides for ieee final year civil engineering ce or ieee civil construction btech be mtech students for the year 2017 2018.

Description cellular lightweight concrete clc is produced by the mixing of sand fly ash cement foam and water in requisite proportion in ready mix plant or ordinary concrete mixer. The purpose of the foam is to supply a mechanism by which a relatively high proportion of stable air voids can be induced into the mixture and produce a cellular or porous solid upon curing of the mixture.